Basic version

- Working width 3m

- 24 sowing coulters

- 22 plates with a diameter of 460 mm in the ATOS LIGHT unit

- Own plumbing

- Seeding device

- Electronic regulation of blower speed

- Monitoring for clogging of tubes

- Automatic pathing

- Automatic markers (broken)

- GPS module

- Grain level sensor in the tank

- 600 mm tubular roller

- Wireless and Touch Monitor

- Side screens

- Platform

- Hydropack

| Working width | Mass | Disc coulters | Efficiency 10 km/h | Power demand |

|---|---|---|---|---|

| Fortune Seeder pneumatic seeder | 2023kg | 24 art | 3 ha | from 120KM |

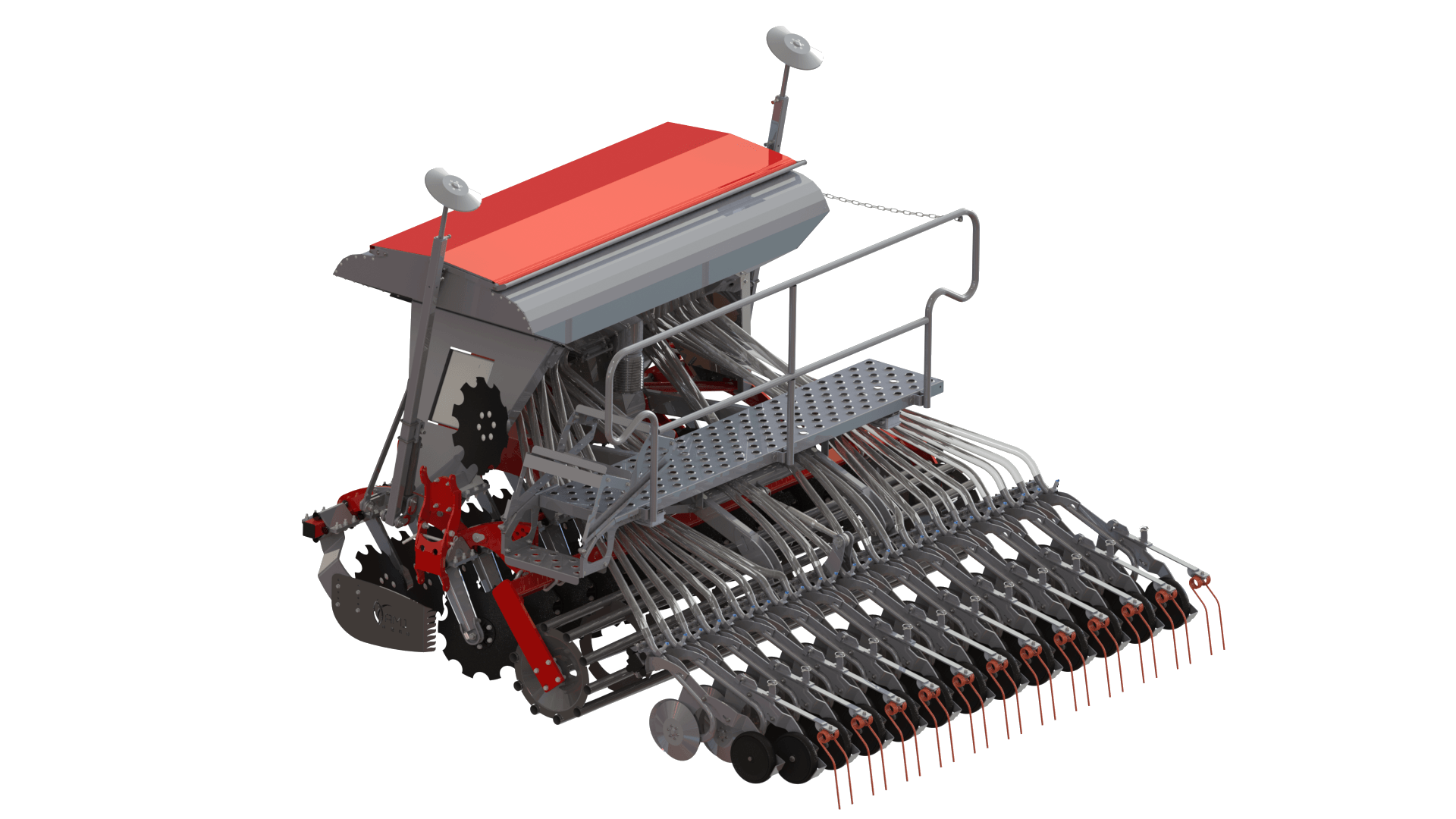

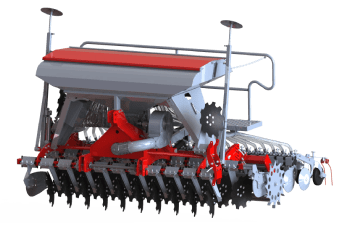

Fortune Seeder pneumatic seeder

Fortune Seeder pneumatic seeder

24 seed tubes enable surgical precision of sowing at a working width of 3 meters. The seeder has its own hydraulics and electronic control with a touch display. Thanks to the use of the latest technological solutions, the FORTUNE SEEDER 3m seeder allows you to achieve extremely precise sowing from 1 kg/ha to 400 kg/ha at a working speed of up to 20 km/h.

Thanks to the best components and maximum weight reduction, the seeder has low power requirements. The FORTUNE SEEDER 3m seeder has a seed box with a capacity of 700 kg. Each seed tube has its own sensor that allows continuous control of sowing in real time.

The entire seeding and the patency of the seed tubes are constantly monitored and displayed on the touch LCD display. The FORTUNE SEEDER 3m seed drill is a milestone in the development of every farm.

The "FORTUNE SEEDER 3m" pneumatic seeder, fully designed in cooperation with engineers and technologists from BRASTAL. 24 seed tubes enable surgical precision of sowing at a working width of 3 meters. The seeder has its own hydraulics and electronic control with a touch display.

Thanks to the use of the latest technological solutions, the "FORTUNE SEEDER 3m" seeder allows you to achieve extremely precise sowing from 1 kg/ha to 400 kg/ha at a working speed of up to 20 km/h. Using the best quality components, while making the machine lighter, the seeder has low power requirements.

The "FORTUNE SEEDER 3m" seeder has a seed box with a capacity of 750 kg. Each seed tube has its own sensor that allows continuous control of sowing in real time. All sowing and the patency of the seed tubes are constantly monitored and displayed on the display.

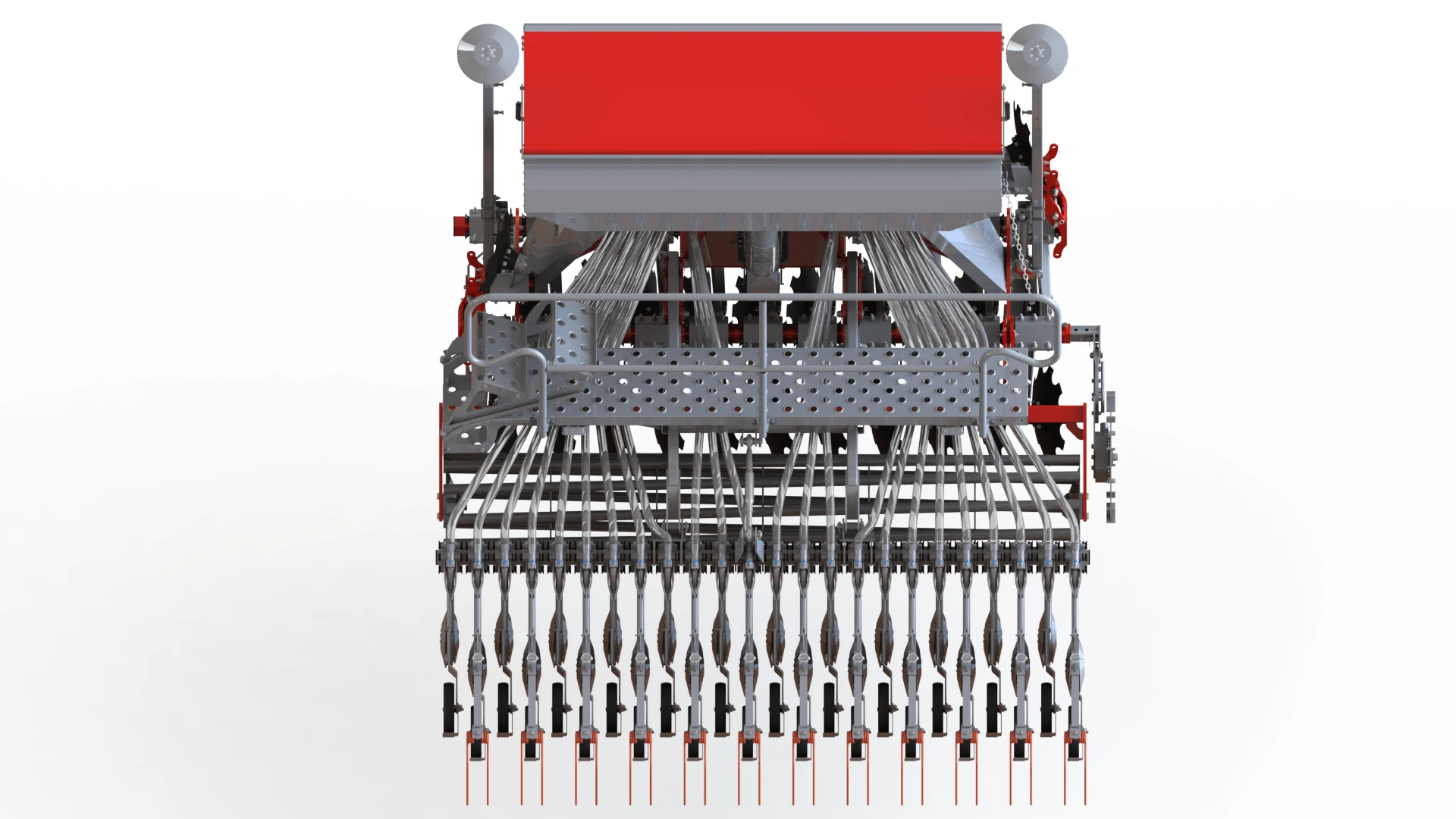

Seeding coulters

The seeder has 24 sowing coulters designed by engineers and manufactured by BRASTAL. The coulters are double-disc, designed to best fulfill their role. Each coulter is equipped with two discs mounted on hubs, which have a well-sealed bearing to prevent any dirt from getting inside. Each coulter is separately amortized. The plates are offset from each other so that they clean each other.

The seed tube has been designed in such a way that, thanks to an appropriate air stream, the seed is transported into the groove made by the discs. In the next sowing phase, the seed is pressed by the press wheel. The pressure wheel additionally maintains the working depth of the coulter.

The coulters are equipped with a harrow, which works great in all conditions, even in those where there are a lot of crop residues on the ground surface. It is possible to freely assemble or disassemble the scraper, depending on your needs. The spring element is made of high-quality spring steel.

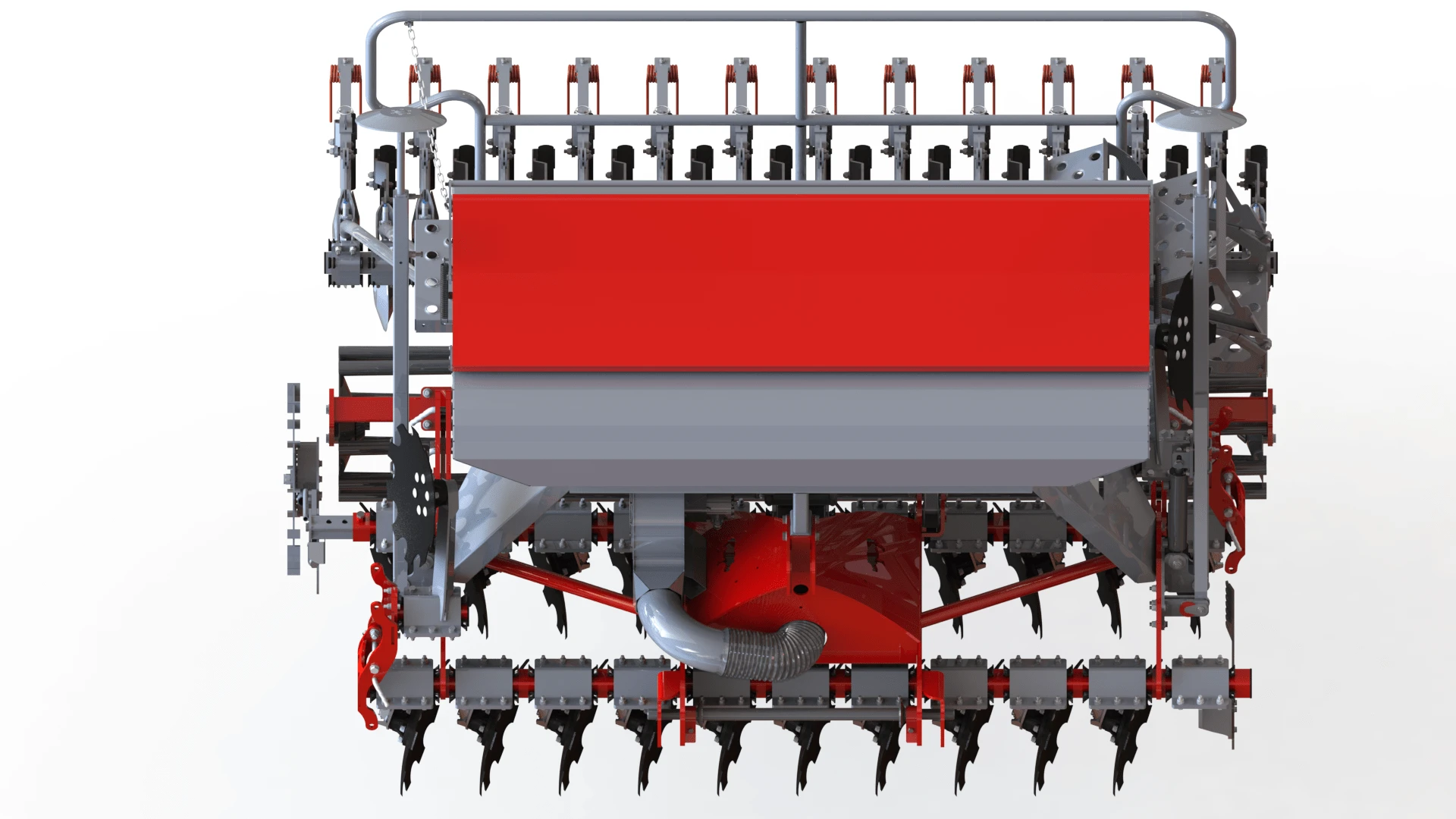

Internal hydraulics

The seeder is equipped with its own hydraulic drive. What are the benefits of having your own hydraulic drive? All seeder hydraulics are built according to the performance needs of the seeder. The pump drive is obtained from the PTO shaft, which can operate at 540 eco speed. Thanks to this application, we can successfully aggregate tractors that do not have oil flow regulation or have limited power.

The hydraulic system is supplemented with special hydraulic oil. It is not possible to mix the oil. In this system, it is possible to adjust the blower speed, change markers, raise and lower the sowing coulters. The system has its own oil filter. The system has an oil tank which, thanks to its shape and surface, serves as a cooler.

Seeding device

The sowing device is made of acid-resistant steel. Thanks to the use of this type of material, the user does not have to worry about corrosion in the sowing device and can successfully sow seed covered with stain. The device has a sensor that monitors the amount of seed in the device. If it is missing, the operator receives a message on the touch screen inside the tractor.

The device has replaceable elements (rollers) that can be easily replaced if necessary. The rollers are adjusted to the granulation and the amount of grain sown per hectare. The device is driven by a Servo motor with a gear and feedback control, which translates into sowing accuracy.

The device has a gate that separates the grain from the tank from the device. The device allows the remaining amount of grain to be released from the tank without the need to remove it through the upper part of the tank. If the seeding device is blocked, it is possible to open it and remove the foreign body.

Electronic regulation of blower speed

The seeder is equipped with a fan that maintains a constant set rotor speed without affecting the PTO speed, engine speed or tractor driving speed. This solution translates into sowing accuracy. The blower speed can be set both via the touchscreen monitor and mechanically in the event of a fault.

Monitoring for clogging of tubes

Each coulter is equipped with a special rubber grip, where a sensor is located to detect and inform the operator (via a monitor in the cabin) about the coulter being clogged. Thanks to this solution, it is possible to work in the most unfavorable conditions without fear of clogging the tubes. Numbering each tube makes it easier to quickly locate a clogged coulter out of 24 pieces.

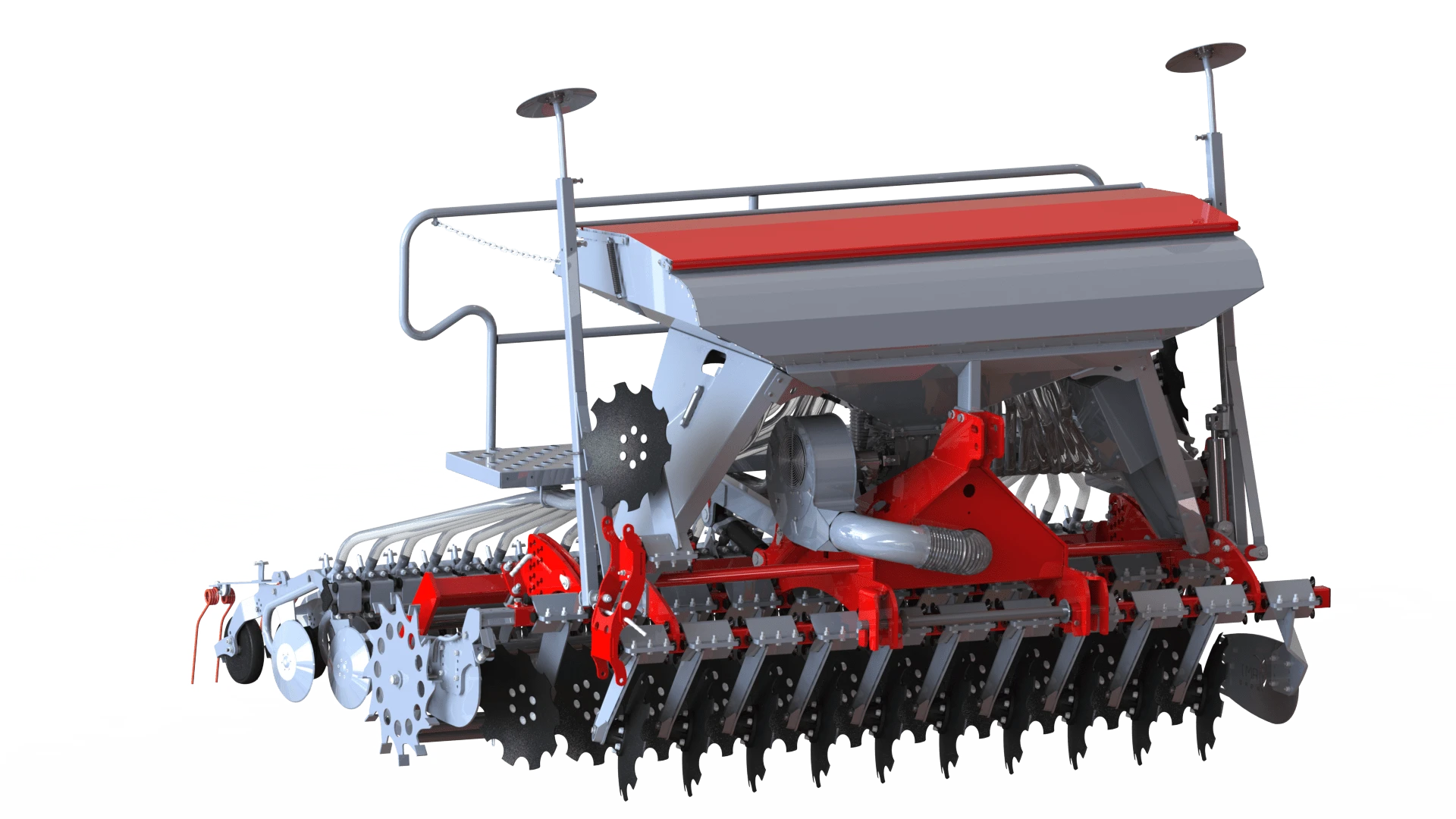

Automatic pathing

The FORTUNE SEEDER seeder is standardly equipped with automatic closing of path sections. Section closing is performed automatically. In order for the seeder sections to close and open properly, the operator must select the correct sprayer width on the touch screen.

Automatic markers

Like pathing, the markers change automatically after each turn. The marker is changed using hydraulic actuators, without direct operator intervention. Both markers are equipped with high-quality plates, adjustable length and a well-sealed hub. In order to facilitate loading of seed material (big bag) by another tractor equipped with a loader, the marker is broken. An additional advantage of this solution is that it makes it easier to hide the seeder in a low room.

GPS module

The seeder works with a GPS module. Thanks to this application, it is possible to precisely determine the operating speed of the seeder, which translates into sowing accuracy. The GPS module starts working from 2 km/h. At the first moment of operation, the seeder has a function to eliminate this delay. Thanks to this, it is possible to reduce the sowing delay to zero.

Grain level in the tank

The seeder has a tank with a capacity of 1000 l, which translates into 750 kg of wheat. The tank is made of galvanized and powder-coated sheet metal, which ensures high anti-corrosion resistance. There are two capacitive sensors inside the tank. In addition, an additional sensor is located in the seeding device. The seed quantity level is displayed on the monitor screen.

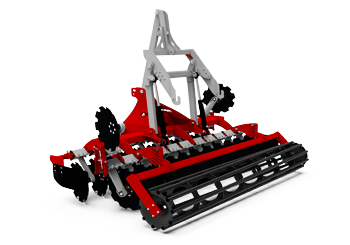

ATOS LIGHT disc unit

The ATOS LIGHT disc cultivator is a light cultivator designed for shallow work (5-15 cm) in order to stir up the soil before sowing. It is equipped with 22 plates with a diameter of 460 mm. The spacing between the front and rear disc axles is 70 cm. As standard, it is equipped with a maintenance-free hub manufactured by AMJAGRO.

Each disc has its own cushioning, which protects the hub, disc and leg against damage. The machine's structure is powder-coated. Before painting, the structure goes through a shot-blasting process, which has a huge impact on preparing the machine for painting, which translates into high anti-corrosion protection. The compact and durable structure was designed with the seeder in mind. As standard, ATOS LIGHT has a drawbar and side screens.

Platform

The seeder is equipped with a solid platform. The platform has stable steps that do not touch the ground. Side platform: Thanks to this platform, we can transfer seed from the trailer or vehicle from the load level. The platform has a strong and solid barrier that ensures safety during use.

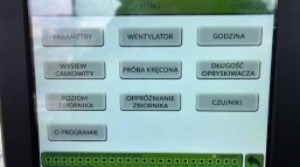

Wireless touch monitor

The standard equipment of the FORTUNE SEEDER includes a wireless and touch monitor, mounted using a triple suction cup. Power is required for the monitor. The monitor communicates wirelessly with the controller. The monitor displays operating parameters and informs the operator about any problems during sowing.

The controller includes the following options: setting the blower speed, calibration test with setting the sowing parameters, emptying the tank of seed, path settings and other controller parameters.

Hydropack

A device used in our pneumatic seeder for smooth adjustment of the coulter height. Particularly useful on turns, it prevents the sowing coulters from colliding with the ground or other obstacles. Eliminates clogging of tubes. Mode of action: Automatically or manually, after selecting any option on the monitor, the hydropack can float 1.5m above the ground. Its design includes adjustment of the working depth of the coulters, changes of the inclination angle and change of the coulter pressure, which allows for work in the most demanding soils.

Coulter pressure

The coulter pressure is an adjustable link whose extension or retraction affects the pressure of the sowing coulters. It is especially important when sowing rapeseed. Thanks to this device, it is possible to sow rapeseed as shallowly as possible or deep enough, depending on the grain or soil conditions.

Photo gallery of the Fortune Seeder pneumatic seeder

Photo gallery of the Fortune Seeder pneumatic seeder

Let's talk, contact us

Agricultural machinery: cultivation and sowing aggregates, disc harrows, cultivation rollers i tilling sets.

Warranty and post-warranty service

We provide transport of agricultural aggregates and machines, warranty service and an assortment of spare parts.Full warranty service for agricultural machines

We use the best materials and components. The solid structures of agricultural units are characterized by high durability, which means that the machines serve our customers reliably for years.

Product advice and support

We have gained a position on the market thanks to professional support. We will advise you which our agricultural units are optimal for you.Consulting and support regarding agricultural machinery

Our offer is constantly developing, and we approach all clients individually. Please contact us - we will advise you and answer any questions regarding our agricultural units.

Become our partner

We work with a constantly growing group of distributors in Poland and abroad. Contact us for cooperation.Become a distributor of agricultural units

If you want to become a distributor of our agricultural machines (in Poland or abroad), contact our employees to learn the details of the special offer for partners.

Our partners

Other agricultural machinery

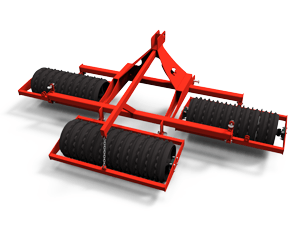

For leveling the field and breaking up clods in the soil. Improves soil structure by rolling - better seed-soil contact and plant emergence.

For leveling the field and breaking up clods in the soil. Improves soil structure by rolling - better seed-soil contact and plant emergence.

Disc units are designed for crushing, cutting and loosening soil using two rows of toothed discs.

Semi-mounted tillage and seeding unit. Both for cultivating the land after harvest and during sowing. Two rows of toothed plates.